What is Acoustic emission testing ?

Acoustic emission (AE) is the phenomenon of radiation of acoustic (elastic) waves in solids that occurs when a material undergoes irreversible changes in its internal structure, for example as a result of crack formation or plastic deformation due to aging, temperature gradients or external mechanical forces. In particular, AE is occurring during the processes of mechanical loading of materials and structures accompanied by structural changes that generate local sources of elastic waves. This results in small surface displacements of a material produced by elastic or stress waves generated when the accumulated elastic energy in a material or on its surface is released rapidly. The waves generated by sources of AE are of practical interest in structural health monitoring (SHM), quality control, system feedback, process monitoring and other fields. In SHM applications, AE is typically used to detect, locate and characterise damage.

The Acoustic Emission NDT technique is based on the detection and conversion of these high frequency elastic waves to electrical signals. This is accomplished by directly coupling piezoelectric transducers on the surface of the structure under test and loading the structure. Sensors are coupled to the structure by means of a fluid couplant and are secured with tape, adhesive bonds or magnetic hold downs. The output of each piezoelectric sensor (during structure loading) is amplified through a low-noise preamplifier, filtered to remove any extraneous noise and furthered processed by suitable electronic equipment.

Applications of acoustic emission testing

- Laboratory & R&D studies

- In field inspection

- Structural integrity evaluation

- Vessels testing [ambient, hot or cryogenic, metallic and FRP, spheres]

- Tank bottom testing

- Nuclear components inspection (valves, lift beams, steam lines)

- Corrosion detection

- Pipeline testing

- Transformers testing (Partial Discharge)

- Railroad tank car testing

- Tube trailers & high pressure gas cylinders

- Reactor & high energy piping testing

- Aging aircraft evaluation

- Advanced materials testing (composites, ceramics)

- Production quality control

- Rocket motor testing.

Acoustic Emission for Laboratory Testing

Acoustic Emission inspection is a powerful aid to materials testing and the study of deformation, fracture and corrosion. It gives an immediate indication of the response and behavior of a material under stress, intimately connected with strength, damage and failure. Acoustic Emission is used also for monitoring chemical reactions including corrosion process, liquid solid transformations, phase transformations.

Acoustic Emission in field testing

Many codes and standards exist for Acoustic Emission testing of vessels, from transportation gas cylinders and railroad tanks to thousands tons storage tanks. Because only active defects and deterioration produce Acoustic Emission no time is wasted on inactive defects which are not threatening structural integrity.

Global monitoring- 100% Inspection of the structure

A major advantage of Acoustic Emission inspection is that does not require access to the whole examination area. E.g. for covering a total area of a 16m-diameter sphere 30-40 sensors are needed. Thus, the cost of the test is significantly less than inspection with conventional NDT methods (for 100% inspection and scanning of the whole area). Identified problem areas can be inspected using conventional NDT methods.

Testing with insulation /high temperature processes

In cases of insulation, only small holes in insulation are required for sensors mounting, resulting in more cost savings. In cases of high temperature processes, wave-guides are used to guide the Acoustic Emission waves from the hot surface to the edge where the sensor is mounted. Finally, in large cryogenic vessels, permanent sensors are mounted under insulation for periodic inspection control.

On-line testing

As the method records defects in real time, it offers the possibility of on-line inspection, e.g. during hydrostatic testing. Other types of on-line stress application are introducing of gas into the upper vapor space, temperature control etc.

Rapid inspection

The actual Acoustic Emission test takes a matter of hours, and, in some cases, even less. There is no comparable technique which can provide 100% volumetric inspection.

Cost Reduction

The use of Acoustic Emission results in considerable reduction in plant maintenance costs, while increasing the available information about plant integrity. Plant downtime for inspection is also minimized.

Permanent recording of test

Acoustic Emission data are digitized and stored on a PC, providing permanent recording of the test to be used at any time for re-evaluation and post processing analysis.

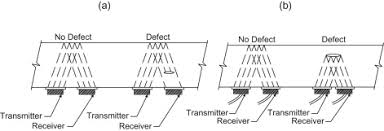

Defect Location

When more that one sensors are used, Acoustic Emission source can be located and, thus, the defective area. Location is based on the wave propagation principles within the materials and is effectuated by measuring the signal’s arrival time to each sensor. By comparing the signal’s arrival time at different sensors, the flaw’s location can be defined through triangulation.

Linear location is used on long gas cylinders, planar (2-dimensional) location for thick walled and gas filled vessels, while 3-dimensional location is used for power transformers and concrete structures.

Equipment

Acoustic Emission Sensor Collage

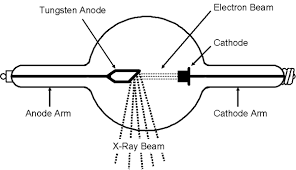

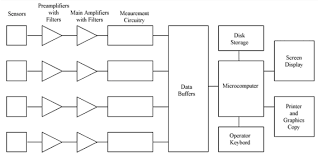

Acoustic emission testing can be performed in the field with portable instruments or in a stationary laboratory setting. Typically, systems contain a sensor, preamplifier, filter, and amplifier, along with measurement, display, and storage equipment (e.g. oscilloscopes, voltmeters, and personal computers). Acoustic emission sensors respond to dynamic motion that is caused by an AE event. This is achieved through transducers which convert mechanical movement into an electrical voltage signal. The transducer element in an AE sensor is almost always a piezoelectric crystal, which is commonly made from a ceramic such as lead zirconate titanate (PZT). Transducers are selected based on operating frequency, sensitivity and environmental characteristics, and are grouped into two classes: resonant and broadband. The majority of AE equipment is responsive to movement in its typical operating frequency range of 30 kHz to 1 MHz. For materials with high attenuation (e.g. plastic composites), lower frequencies may be used to better distinguish AE signals. The opposite holds true as well.

Ideally, the AE signal that reaches the mainframe will be free of background noise and electromagnetic interference. Unfortunately, this is not realistic. However, sensors and preamplifiers are designed to help eliminate unwanted signals. First, the preamplifier boosts the voltage to provide gain and cable drive capability. To minimize interference, a preamplifier is placed close to the transducer; in fact, many transducers today are equipped with integrated preamplifiers. Next, the signal is relayed to a bandpass filter for elimination of low frequencies (common to background noise) and high frequencies. Following completion of this process, the signal travels to the acoustic system mainframe and eventually to a computer or similar device for analysis and storage. Depending on noise conditions, further filtering or amplification at the mainframe may still be necessary.

Schematic Diagram of a Basic Four-channel Acoustic Emission Testing System

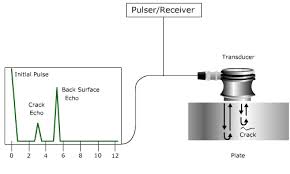

After passing the AE system mainframe, the signal comes to a detection/measurement circuit as shown in the figure directly above. Note that multiple-measurement circuits can be used in multiple sensor/channel systems for source location purposes (to be described later). At the measurement circuitry, the shape of the conditioned signal is compared with a threshold voltage value that has been programmed by the operator. Signals are either continuous (analogous to Gaussian, random noise with amplitudes varying according to the magnitude of the AE events) or burst-type. Each time the threshold voltage is exceeded, the measurement circuit releases a digital pulse. The first pulse is used to signify the beginning of a hit. (A hit is used to describe the AE event that is detected by a particular sensor. One AE event can cause a system with numerous channels to record multiple hits.) Pulses will continue to be generated while the signal exceeds the threshold voltage. Once this process has stopped for a predetermined amount of time, the hit is finished (as far as the circuitry is concerned). The data from the hit is then read into a microcomputer and the measurement circuit is reset.