History of Ultrasonic testing .

On May 27, 1940, U.S. researcher Dr. Floyd Firestone of the University of Michigan applies for a U.S. invention patent for the first practical ultrasonic testing method. The patent is granted on April 21, 1942 as U.S. Patent No. 2,280,226, titled “Flaw Detecting Device and Measuring Instrument”. Extracts from the first two paragraphs of the patent for this entirely new nondestructive testing method succinctly describe the basics of such ultrasonic testing. “My invention pertains to a device for detecting the presence of inhomogeneities of density or elasticity in materials. For instance if a casting has a hole or a crack within it, my device allows the presence of the flaw to be detected and its position located, even though the flaw lies entirely within the casting and no portion of it extends out to the surface.The general principle of my device consists of sending high frequency vibrations into the part to be inspected, and the determination of the time intervals of arrival of the direct and reflected vibrations at one or more stations on the surface of the part.”

What is meant by ultrasonic testing?

Ultrasonic testing (UT) is a non-destructive test method that utilizes sound waves to detect cracks and defects in parts and materials. It can also be used to determine a material’s thickness, such as measuring the wall thickness of a pipe.

What is ultrasonic testing in welding?

Ultrasonic testing of welds. Ultrasonic testing technology is based on the ability of high-frequency oscillations (about 20,000 Hz) to propagate into the metal and be reflected from surface scratches, voids, and other discontinuities.relative size of the defect – through the amplitude of the reflected pulse.

How ultrasonic testing works ?

In ultrasonic testing, an ultrasound transducer connected to a diagnostic machine is passed over the object being inspected. The transducer is typically separated from the test object by a couplant (such as oil) or by water, as in immersion testing. However, when ultrasonic testing is conducted with an Electromagnetic Acoustic Transducer (EMAT) the use of couplant is not required.

There are two methods of receiving the ultrasound waveform: reflection and attenuation.

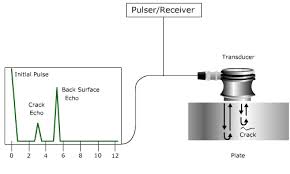

In reflection (or pulse-echo) mode, the transducer performs both the sending and the receiving of the pulsed waves as the “sound” is reflected back to the device. Reflected ultrasound comes from an interface, such as the back wall of the object or from an imperfection within the object. The diagnostic machine displays these results in the form of a signal with an amplitude representing the intensity of the reflection and the distance, representing the arrival time of the reflection.

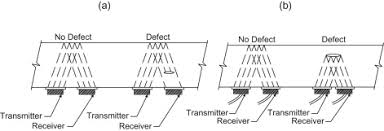

In attenuation (or through-transmission) mode, a transmitter sends ultrasound through one surface, and a separate receiver detects the amount that has reached it on another surface after traveling through the medium. Imperfections or other conditions in the space between the transmitter and receiver reduce the amount of sound transmitted, thus revealing their presence. Using the couplant increases the efficiency of the process by reducing the losses in the ultrasonic wave energy due to separation between the surfaces.

Advantages

- High penetrating power, which allows the detection of flaws deep in the part.

- High sensitivity, permitting the detection of extremely small flaws.

- In many cases only one surface needs to be accessible.

- Greater accuracy than other nondestructive methods in determining the depth of internal flaws and the thickness of parts with parallel surfaces.

- Some capability of estimating the size, orientation, shape and nature of defects.

- Some capability of estimating the structure of alloys of components with different acoustic properties

- Non-hazardous to operations or to nearby personnel and has no effect on equipment and materials in the vicinity.

- Capable of portable or highly automated operation.

- Results are immediate. Hence on the spot decisions can be made.

Disadvantages

- Manual operation requires careful attention by experienced technicians. The transducers alert to both normal structure of some materials, tolerable anomalies of other specimens (both termed “noise”) and to faults therein severe enough to compromise specimen integrity. These signals must be distinguished by a skilled technician, possibly requiring follow up with other nondestructive testing methods.

- Extensive technical knowledge is required for the development of inspection procedures.

- Parts that are rough, irregular in shape, very small or thin, or not homogeneous are difficult to inspect.

- Surface must be prepared by cleaning and removing loose scale, paint, etc., although paint that is properly bonded to a surface need not be removed.

- Couplants are needed to provide effective transfer of ultrasonic wave energy between transducers and parts being inspected unless a non-contact technique is used. Non-contact techniques include Laser and Electro Magnetic Acoustic Transducers (EMAT).